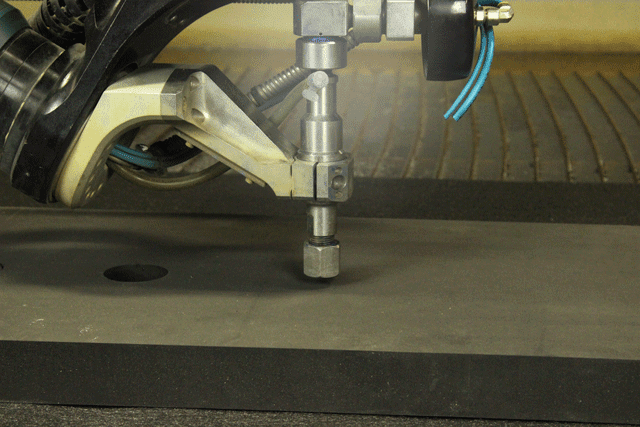

Waterjet cutting is a versatile cutting process that is used in the fabrication of a very wide variety of materials.

Abrasive waterjet cutting introduces an ‘abrasive’ into the waterjet and is used for cutting metal and harder materials.

Advantages

- Clean process

- Water-only waterjet cutting is ideal for soft or delicate materials e.g. foam fabrication

- Leaves the best edge

- Reduced lead-time

- Used with a wide variety of material densities, foam, rubber and metals

- Cuts tapers and bevels easily

- Cold cutting process that does not transfer heat or change structure of material