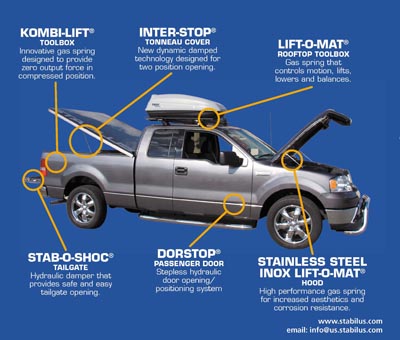

Gas springs are generally used for improving or assisting in the ease of lifting or lowering objects in access applications such as lids, windows, doors, etc and for adjustable applications such as seats or tables. Depending on the application, gas springs can also be referred to as gas shocks, lifts, props, struts or dampers.

Gas springs are commonly placed halfway between the hinge and the center of the object being lifted.

Positioning the gas spring 'rod-down' ensures that the oil inside the spring is in the right position at the bottom of the gas spring so the piston travels through it at the end of the stroke. This maximizes the dampening effect. Consistent lubrication is also good for the life expectancy of the gas spring. Positioning the gas spring in this way can also decrease the rate at which nitrogen gas escapes, preserving the force and function of the gas spring for a longer length of time.

Gas springs tend to lose pressure (i.e. nitrogen gas) and therefore force over time.

Choosing a gas spring with an extension force that is slightly greater than what is needed for the application can prolong its life expectancy. If the wrong gas spring is selected for the application and the force is too low, for example, then the object will require more hand force than was intended for it to move and it may not stay open or lifted as desired. This makes applications less ergonomic, uncomfortable to operate and decreases performance.

The force of the gas spring also varies with temperature.

As temperature rises and falls the internal pressure of the spring rises and falls making applications like car trunks and lids harder to lift at colder temperatures.

The extension force required for an application depends directly on the weight of the object, the center of gravity points and the link points of the gas spring. The dimensions of the gas spring are contingent on the extension force and the required stroke but by changing the way the gas spring is mounted can maximize the available installation space.

Even if you're unsure about the extension force required we can assist in selecting the best gas spring with some basic information from you.

Gas springs can provide a variety of options such as stopping the object in multiple positions, lighting or end position stopping.

Locking gas springs work according to the same principles as regular gas springs but can be set to lock in any position along the stroke.

To maximize the performance and safety of your gas springs:

- Use standard gas springs in the rod-down position

- Avoid cycling the piston in and out more than 3-4 times a minute

- Ensure end fittings are aligned to lessen side-load forces

- Don't puncture, heat or try to lubricate them

Source: Stabilus

|